15

2021

-

09

Summer cooling tower operation overflow what happened? Cooling tower overflow solution

Classification:

Cooling tower overflow status and solutions

Multiple counterflow cooling towers, selected for automatic control operation, use electric valves at the cooling tower inlet and not installed on the tower outlet. Under low load, operation of a single cooling tower with less water in the operating tower results in a higher water level in the cooling tower catch basin, which can cause the cooling tower to overflow.

In another case, the cooling tower can overflow. When multiple cooling towers of different sizes are connected together, the water levels in the towers are different, the water pans are low and the tower must overflow.

Cooling tower overflow solutions.

1. Install electric valves on each outlet of the cooling equipment, operating in pairs with the valves on the inlet. When the tower stops working, close the electric valve on the return pipe at the same time and close the electric valve on the return pipe at the same time to maintain the water balance of the water collection tray.

2. Add a pipe at the bottom of each parallel tower catchment tray, connect it through a larger balance pipe and increase the diameter of the outlet pipe, which is simple and easy to do.

The above is just a simple tip, according to the experiment, when multiple sewage cooling towers operating in parallel, the piping method generally has the following five methods.

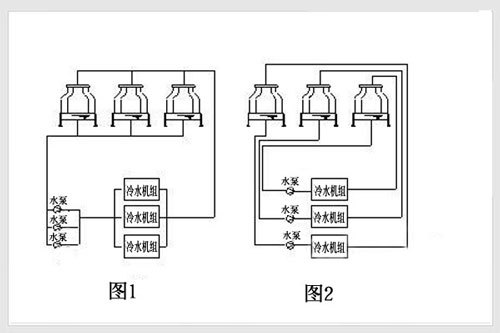

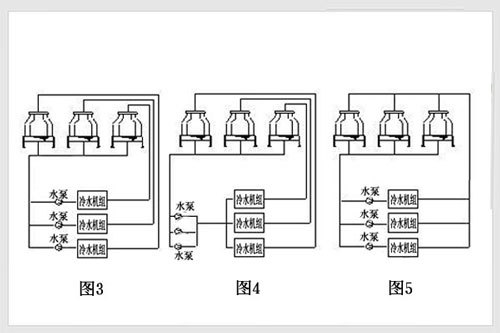

Cooling tower piping method 1

Cooling tower parallel piping layout 2

According to our experience, the layout of the cooling tower and connecting pipes in Figure 2 is the most complicated and takes up a lot of space, but the flow distribution is reasonable and the operation is reliable. .3. The piping layout is simple, but cooling tower overflow and water replenishment occur frequently, mainly due to.

1. In general, the electric valve is installed on the cooling tower inlet, not installed on the outlet and not operating cooling tower water valve is closed, but the outlet is connected. During individual operation, the water level in the cooling tower water pan rises, causing the cooling tower to overflow while the water pans of other non-operating towers are constantly replenished with water.

2. Uneven water distribution in each cooling tower is usually a problem with the piping connected to the cooling tower. Some towers have low resistance in the inlet pipe and high resistance in the outlet pipe; more water in and less water out, causing the cooling tower to overflow. On the contrary, some towers constantly replenish water.

3. When several cooling towers of different sizes are connected together, the water level in the tower is different, and the cooling tower with low water tray is bound to overflow.

Based on the above problems, attention should be paid to the cooling tower and pipe balance in the design, including water level balance and water balance. Generally speaking, for the combination of water intake methods, the following countermeasures are used.

1. For Figure 1, the electric valve is set in the inlet and outlet of each cooling tower, and is controlled by a chain with the pump and cooling tower fan.

2. for Figure 1, 3, 4, each cooling tower bit (including different sizes of towers) control in the same height, the height difference shall not exceed 30mm. install balance pipe between the cooling tower, and increase the diameter of the outlet pipe.

3. For Figure 1 and 4, in order to balance the water volume of each cooling unit, a balancing valve can be installed in the drainage port of each cooling unit.

With such improvements, the previous problems can be well solved, and then the piping can be completed by simple wiring to facilitate the connection of multiple cooling towers.

These problems can occur in summer when the cooling tower system is working under high load and the wiring is not handled properly. Cooling tower water solution is the key to cooling tower system maintenance. Company personnel should be aware of all abnormalities in cooling towers. Cooling tower overflow is a small part of circulating water treatment. If you want to learn more about the basics of cooling tower failure, you can call the phone number of cooling tower manufacturer Guangdong Telling Air Conditioning.

Related News

What are the benefits of regular cleaning of cooling tower packing, the reasons for regular cleaning of cooling tower packing, how much do you know?

MORE +Cooling tower packing cleaning which is better? Guangdong Telling air conditioning is engaged in cooling tower cleaning, cooling tower chemical cleaning...

MORE +What is the role of Maliliang machine cooling tower accessories in the cooling tower renovation

The heat exchange capacity of the cooling tower is mainly determined by the gas-to-water ratio, and the traditional technology is not efficient and effective enough. If the cooling tower parts with Marley good machine for its transformation, then the shaft power of the water turbine and motor power can be achieved the same. The structure, shape, specifications and cooling principle of the cooling tower do not need to be changed.

MORE +What are the things to do after the installation of Liangqi cooling tower reducer? Things to do after installation of Liangqi cooling tower reducer

MORE +Jiangmen Wanyang Cooling Equipment Co., Ltd

TEL:18933186699

TEL:hy9698@126.com

ADD:No. 8, Longwan Road, Zhishan Town, Heshan City